|

||

|

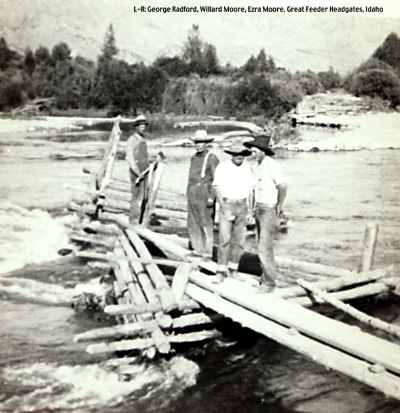

Even for people whose lives consisted of challenges met and mastered, the Great Feeder Headgates and the many other irrigation

projects near it, were mighty accomplishments in their time and place, bringing vital water to farmlands in the Ririe, Rigby,

Rexburg and Idaho Falls area of Southeastern Idaho

|

|||

|

The book "Pioneer Irrigation" is a great source of historical information on the building of the irrigation projects that take water from the Snake River above Ririe, Idaho and feed it, via a system of canals, to the nearby farmlands. The people, their dreams and hardships, and the successes of their determined efforts to get water onto their farm land, are chronicled in a clear and simple manner. Many of our ancestors, including Morgans, Radfords, Moores and Rysets, are mentioned in the book. There is a picture of Thomas Morgan in it.  George Radford and Willard Moore are shown above standing on the first rip-rap of logs filled with rocks, called a Crib Wheel, that was placed in the Snake River as a forerunner to the dam that would divert water into the Great Feeder Irrigation Canal. Later the log structure was replaced by a concrete diversion structure. George Radford mailed this picture to his cousin Ezra Morgan but there must have been more than one copy made of it because this picture is also on page 178 of the Pioneer Irrigation book pictured above. George Radford and Willard Moore worked for many years of their lives on the construction, mainenance, and management of the

Great Feeder Headgates. Willard Moore, husband of Annie Lydia Morgan, was watermaster of the Great Feeder Headgates for thirty

years. Willard was first hired in 1904 and he invented a horse powered swinging arm to remove logs and debris from the headgates.

Later he used a Model T Ford, but with a wary axeman standing by to cut the car loose in case the logs began to pull it into

the river.

In the picture above Buck scrapers, pulled by both horse and mule teams, are being used to load wagons with soil so it can be transported to where it is needed. The loaded Buck scraper is dragged to the top of the ramp and then dumped through a metal grid (by flipping the scraper up, over and forward) into a wagon that has been driven into the "underpass" below. The wagons then had to be unloaded by hand with shovels. The initial work for the Great Feeder Headgates was done with Buck scrapers. The wagon loading ramp in the picture above was built with Buck scrapers so Buck scrapers could be used to load wagons.  Horses and Buck scrapers were used for earth moving in building the early headgates and digging the canals. Later a new technology emerged, the Fresno scaper. Both scapers were hand operated but the Fresno was larger. The men in the picture above are using Fresno scrapers pulled by four horse hitches. The headgate of the Great Feeder Canal was the largest in the United States when it was built. It supplies water to some twenty major canal systems and supplies irrigation water to 100,000 acres of valley farms. The Great Feeder incorporation was put on record the first day of January, 1895, but the paperwork and construction had started long before because the Great Feeder Celebration, which attracted quite a gathering for the opening of the headgates, was reported in the Idaho Falls Times on June 27, 1895. Work continued on various diversion dams and canals well into the early 1900's. For pictures of the Fresno scraper in use building a road in Idaho, and closeups showing details of the Buck and Fresno scrapers, click on the link below. Click on the link above to see what the Great Feeder Headgates looked like in summer 2003. |

|||

And, of course, delivery of water to the crops in the field was the reason the Great Feeder Headgates (and many other headgates) and the system of downstream canals were built. Here, two boys, we don't know whose boys, using hand shovels to flood irrigate a potato crop. |

|||